1. Kanema wosanjikiza umodzi

Imafunika kuti ikhale yowonekera, yopanda poizoni, yosasunthika, yokhala ndi thumba labwino losindikizira kutentha, kutentha ndi kuzizira, mphamvu zamakina, kukana mafuta, kukana mankhwala, ndi anti-blocking.

2. Chikwama cha Aluminium zojambulazo

99.5% aluminiyamu yoyera ya electrolytic imasungunuka ndikukanikizidwa mu zojambulazo ndi kalendala, yomwe ili yabwino ngati gawo lapansi lazotengera zapulasitiki zosinthika.

3. Vacuum evaporation aluminiyamu filimu

Pansi pa vacuum yayikulu, zitsulo zowira pang'ono, monga aluminiyamu, zimasungunuka ndi kutenthedwa ndikuyikidwa pafilimu yapulasitiki pa ng'oma yozizirira kuti ipange filimu yoziziritsidwa ndi zitsulo zonyezimira bwino.

4. Kupaka silicon

Choyikapo chowoneka bwino chokhala ndi zotchinga zapamwamba kwambiri zomwe zidapangidwa m'ma 1980, zomwe zimadziwikanso kuti zokutira za ceramic.

5. Glue (youma / yonyowa) filimu yophatikizika

Mafilimu a monolayer ali ndi zabwino zina komanso zovuta zake.Njira yonyowa yopangira filimu yonyowa: gawo limodzi limakutidwa ndi guluu ndiyeno laminated ndi filimu ina ya gawo lapansi, kenako zowuma ndikuchiritsidwa.Ngati ndi zinthu zopanda porous, kuyanika kwa guluu kungakhale kosauka ndipo ubwino wa nembanemba wamagulu udzachepa.Dry lamination njira: Valani zomatira pa gawo lapansi, lolani zomatira ziume kaye, ndiyeno kanikizani ndi laminate kuti amangirire mafilimu a magawo osiyanasiyana.

6. Extrusion ❖ kuyanika gulu filimu

Pa extruder, thermoplastic imaponyedwa kudzera pa T-die pamapepala, zojambulazo, gawo lapansi la pulasitiki kuti likhale lokutidwa, kapena utomoni wotuluka umagwiritsidwa ntchito ngati chomangira chapakati, ndipo gawo lina la filimu limatentha.Zipangizozo zimakanikizidwa pamodzi kuti zipange filimu yamagulu a "sandwich".

7. Coextrusion filimu yophatikizika

Pogwiritsa ntchito ma extruder awiri kapena atatu, kugawana kufa kophatikizika, laminates pakati pa thermoplastics yogwirizana kuti apange mafilimu ambiri kapena mapepala.

8. Filimu yotchinga yapamwamba

Imatanthawuza zakuthupi zokhala ndi makulidwe a 25.4μm pansi pamikhalidwe ya 23 ° C ndi RH65%, kufalikira kwa okosijeni kumakhala pansi pa 5ml/m.2·d, ndipo chinyonthocho chikudutsa 2g/m2·d.

9. Kanema wosunga mwatsopano komanso wotseketsa

Ethylene gasi adsorption membrane, kuwonjezera zeolite, cristobalite, silika ndi zinthu zina ku nembanemba amatha kuyamwa mpweya wa ethylene wotulutsidwa ndi zipatso ndi ndiwo zamasamba ndikuletsa kupsa kwawo mwachangu.

Anti-condensation ndi fogging film, mkati mwa ma CD filimu ya zipatso zobiriwira zimakhala ndi condensation ndi fogging, zomwe zimakhala zosavuta kuyambitsa mildew pa chakudya.

Kanema wa antibacterial, akuwonjezera zeolite zopanga (SiO2+Al2O3) ndi ntchito yosinthira ion kuzinthu zapulasitiki, kenako ndikuwonjezera zodzaza ndi inorganic zomwe zili ndi ayoni asiliva, kusinthana kwa sodium sodium siliva kumakhala zeolite yasiliva, ndipo pamwamba pake imakhala ndi antibacterial properties.

Kanemayo wakutali wa infrared watsopano amasakanizidwa ndi zodzaza ndi ceramic mufilimu ya pulasitiki, kotero kuti filimuyo imakhala ndi ntchito yopangira kuwala kwakutali, komwe sikungathe kuwononga, komanso kuyambitsa maselo mu chipatso chobiriwira, ili ndi ntchito yosunga kutsitsimuka.

10. Aseptic phukusi filimu

Amagwiritsidwa ntchito kwambiri popanga ma CD a aseptic a chakudya ndi mankhwala, amafunikira kukhala: kukana kutsekereza;mkulu zotchinga katundu ndi mphamvu;kutentha kwabwino ndi kuzizira kozizira (-20 ℃ osati brittle);kukana-kukhomerera singano ndi kukana bwino kupinda;Chosindikiziracho sichidzawonongeka pochotsa kutentha kwambiri kapena njira zina zoletsa.

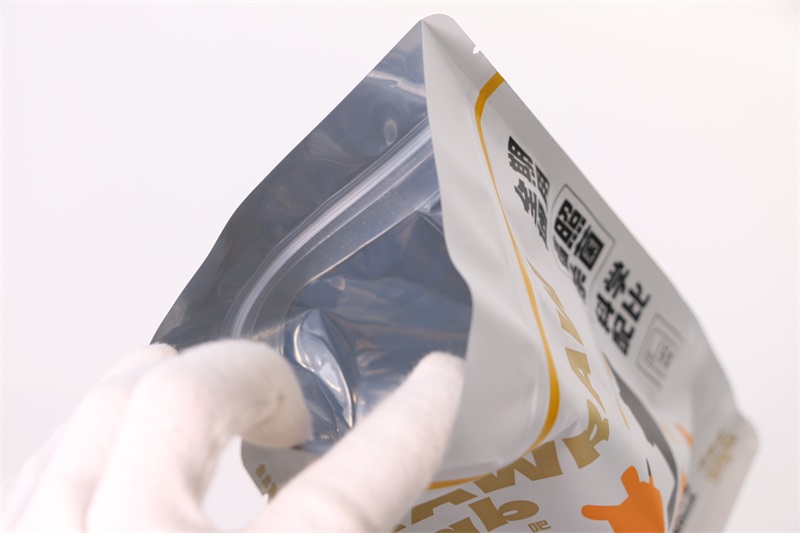

11. Thumba lophikira lotentha kwambiri

M'zaka za m'ma 1960, bungwe la US Naval Research Institute poyamba linapanga ndikugwiritsa ntchito pazakudya zam'mlengalenga.Pambuyo pake, Japan idachilimbikitsa mwachangu ndikuchipanga ndikuchigwiritsa ntchito kumitundu yatsopano yazakudya zosavuta.Matumba ophikira otentha kwambiri amatha kugawidwa kukhala mtundu wowonekera (wokhala ndi alumali wopitilira chaka chimodzi) ndi mtundu wosawoneka bwino (wokhala ndi alumali wazaka zopitilira ziwiri), mtundu wotchinga wapamwamba komanso mtundu wamba.Malinga ndi kutentha kwa njira yolera yotseketsa, imagawidwa kukhala thumba lophika lotsika kutentha (100 ℃, 30min), thumba la kutentha kwapakati (121 ℃, 30min), thumba la kutentha kwambiri (135 ℃, 30min).Zamkati zosanjikiza za thumba la retort zimapangidwa ndi mafilimu osiyanasiyana opangidwa ndi PE (LDPE, HDPE, MPE), kutentha kwambiri kosagwira CPP kapena IPP yokwezeka, etc.

Ubwino waukulu wa matumba ophikira otentha kwambiri:

①Kuphika kutentha kwambiri kumatha kupha mabakiteriya onse, 121℃/30min imatha kupha mabakiteriya onse a botulinum;

②Itha kusungidwa kutentha kwa nthawi yayitali popanda firiji, ndipo imatha kudyedwa mozizira kapena kutentha;

③ The ma CD zinthu ali zabwino chotchinga katundu, zosachepera chakudya zamzitini;

④Kusindikiza kosintha, kusindikiza kokongola ndi kukongoletsa;

⑤ Zinyalala ndizosavuta kuziwotcha.

12. Kutentha kwakukulu kwa ma CD filimu

Kusungunuka kwa zinthuzo kuli pamwamba pa 200 ° C, komwe kuli koyenera kwazitsulo zolimba zolimba / zofewa.

13. Filimu yapulasitiki yowonongeka

Zopangira pulasitiki zowonongeka zimatha kugawidwa muzithunzi, biodegradation, photodegradation ndi biodegradation malinga ndi makina owonongeka.

14. Kutentha shrinkable filimu

Zida ndi PP, PVC, LDPE, PER, nayiloni, etc. Choyamba extrude filimuyo, pa kutentha pamwamba pa kutentha kufewetsa (galasi kusintha mfundo) ndi pansi pa kutentha kusungunuka, mu dziko zotanuka kwambiri, ntchito synchronous kapena masitepe awiri. flat-die stretching njira, kapena calendering njira, kapena zosungunulira Njira kuponyera amachita molunjika molunjika, ndi mamolekyu kutambasula utakhazikika pansi pa galasi kusintha mfundo ndi kutsekedwa.

Nthawi yotumiza: Apr-25-2022